From Spin to Win: Replacing Your Ceiling Fan Motor

April 17, 2025

Illuminate with Ease: Exploring Flexible Track Lighting

April 21, 2025Illuminating Heights: Why Proper Lighting Matters for High Ceilings

LED lighting for high ceilings is essential for effectively illuminating large spaces while maximizing energy efficiency. If you’re looking to light high-ceiling areas, here’s what you need to know:

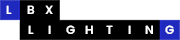

- Best LED options for high ceilings:

- UFO High Bay Lights (round design, ideal for 15-40 ft ceilings)

- Linear High Bay Lights (rectangular design, excellent light distribution)

-

LED Panel Lights (for modern office or retail spaces)

-

Key benefits:

- Energy savings up to 70% compared to traditional lighting

- Minimum lifespan of 50,000 hours (5+ years of continuous use)

- Improved light quality with CRI ratings approaching 90

-

Reduced maintenance costs and fewer replacements

-

Selection factors:

- Ceiling height (determines wattage and lumen requirements)

- Space dimensions and usage

- Desired color temperature (3000K-5700K)

- Mounting options and beam angle

Lighting spaces with high ceilings presents unique challenges that standard fixtures simply can’t handle. The distance between the light source and the working plane means you need powerful, efficient solutions that deliver uniform illumination without wasting energy or requiring frequent maintenance.

Traditional lighting options like metal halide or fluorescent systems often fall short in these environments, creating dark spots, consuming excessive energy, and requiring regular maintenance that disrupts operations.

I’m Michael Eftekhar, and with over 30 years of experience providing LED lighting for high ceilings throughout Houston and surrounding areas, I’ve helped countless businesses transform their high-ceiling spaces with energy-efficient LED solutions that deliver superior illumination while reducing operational costs.

Simple LED lighting for high ceilings word guide:

– LED lighting control systems

– LED lighting for businesses

– LED lighting for parking lots

Understanding LED Lighting for High Ceilings

Ever walked into a warehouse or gymnasium and wondered how they light those massive spaces so well? That’s where LED lighting for high ceilings comes into play. These aren’t your everyday light bulbs – they’re specially designed powerhouses that can illuminate spaces from heights of 15 feet and beyond, all while keeping energy bills in check.

Think of high bay lighting as the heavyweight champion of the lighting world. These fixtures are built specifically for spaces with ceilings ranging from 15 to 40 feet high. They pack enough punch to send light all the way to the floor without losing intensity along the way.

As our lighting design team at LBX Lighting often tells clients, “LED high bay lights are the perfect solution when you’re looking for the best way to illuminate a high-ceiling environment. They combine powerful output with remarkable efficiency, making them ideal for large spaces where traditional lighting falls short.”

Whether you’re lighting a warehouse, sports arena, or retail space with high ceilings, these fixtures deliver consistent, powerful illumination that overcomes the challenges that come with distance.

Types of LED High Bay Lights

When shopping for LED lighting for high ceilings, you’ll mainly encounter two distinct styles: UFO high bays and linear high bays. Each has its own strengths that make it perfect for different settings.

1. Round (UFO) High Bay Lights

Named for their flying-saucer appearance, UFO high bays are compact powerhouses. They’re the go-to choice when you need focused, directional light from above.

UFO high bays typically deliver between 6,900 and 52,000 lumens, with wattages ranging from 50W to 400W. Their circular aluminum design isn’t just for looks – it helps dissipate heat efficiently, extending the fixture’s life. Most come with a 120° beam angle, though you can find options with narrower 30°, 60°, or 90° beams if you need more focused light.

These round warriors excel in warehouses, manufacturing plants, and industrial settings where powerful, directed light is essential.

2. Linear High Bay Lights

If UFOs are the spotlight performers, linear high bays are the team players. With their rectangular design, they spread light more evenly across wider areas.

Linear fixtures are efficiency champions, often delivering an impressive 190-200 lumens per watt. Their sleek, elongated form makes them less obtrusive and more aesthetically pleasing in certain settings. They come in various lengths and configurations to suit different space requirements.

You’ll often find linear high bays in retail environments, gymnasiums, and manufacturing facilities where uniform lighting across a wide area is crucial.

| Feature | UFO High Bay Lights | Linear High Bay Lights |

|---|---|---|

| Design | Circular, compact | Rectangular, elongated |

| Light Distribution | More focused, directional | Wider, more uniform |

| Typical Applications | Warehouses, industrial facilities | Retail, gyms, manufacturing |

| Lumen Efficiency | Up to 150 lumens/watt | Up to 200 lumens/watt |

| Mounting Options | Pendant, hook | Surface, suspension |

| Heat Dissipation | Excellent (360° design) | Good (linear design) |

| Aesthetics | Industrial look | More streamlined appearance |

In our experience at LBX Lighting, choosing between UFO and linear fixtures often comes down to your specific space and what happens there. For pure industrial applications like warehouses, UFO high bays typically win out. But in spaces where looks matter alongside performance, linear fixtures often take the crown.

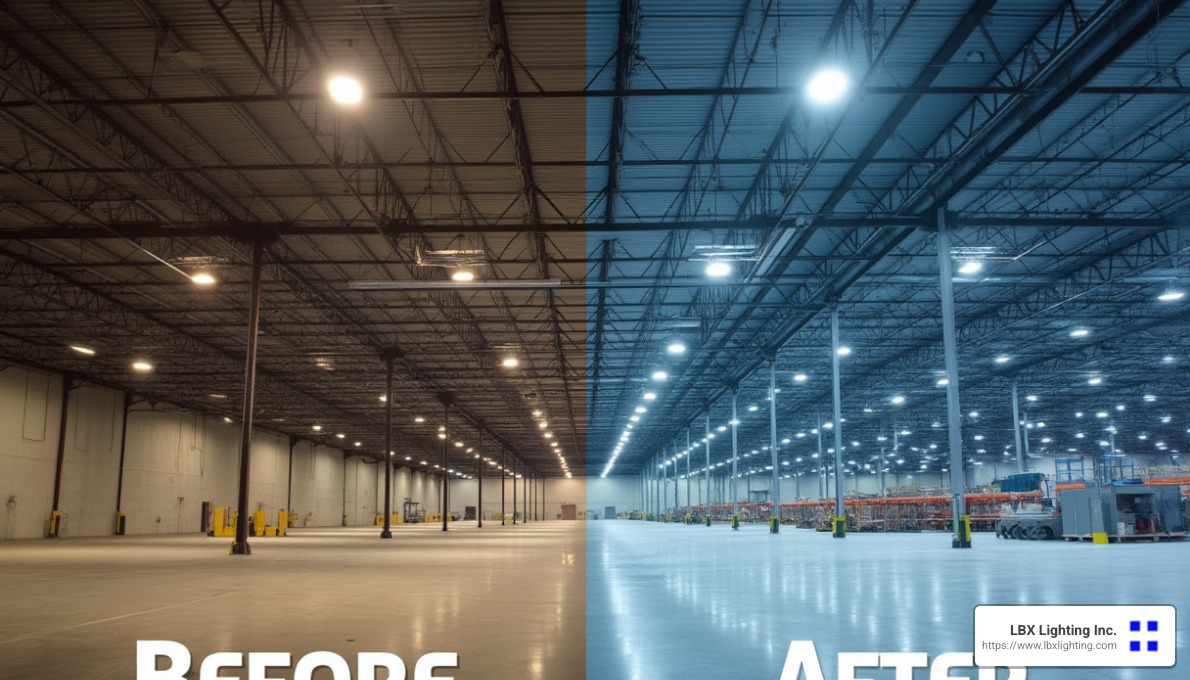

How LED High Bay Lights Differ from Traditional Options

Before LEDs took center stage, high ceiling spaces relied on metal halide, high-pressure sodium, or fluorescent fixtures. The shift to LED lighting for high ceilings isn’t just a trend – it’s a significant upgrade in almost every way.

Energy Efficiency

The numbers don’t lie – LED high bay lights slash energy consumption by around 70% compared to traditional HID fixtures. That’s not pocket change!

One warehouse we worked with switched to LED high bays and saved over $370,000 annually on their electric bill. Even better, their space was actually 36% brighter than before. Talk about a win-win!

Longer Lifespan

Traditional metal halide lamps typically throw in the towel after 10,000-15,000 hours. LED high bays? They keep going for at least 50,000 hours – that’s nearly 6 years of non-stop illumination. Many quality fixtures push well beyond that, sometimes reaching 100,000 hours.

This longevity is especially valuable in high-ceiling environments where changing a light bulb isn’t just grabbing a stepladder – it often requires specialized equipment and significant downtime.

Reduced Maintenance

Beyond just lasting longer, LEDs are more reliable throughout their life. Unlike traditional HID lamps that get noticeably dimmer as they age, LEDs maintain more consistent brightness. And when LEDs do eventually wear out, they fade gradually rather than burning out suddenly, giving you time to plan replacements rather than reacting to unexpected outages.

Higher CRI Ratings

Ever notice how some lights make colors look “off”? That’s where CRI (Color Rendering Index) comes in. LED high bays typically score near 90 on the CRI scale, while HID lighting struggles to break 80. This improved color accuracy is crucial in manufacturing, quality control, and retail environments where seeing true colors matters.

Environmental Impact

Traditional HID lamps contain hazardous materials like mercury that require special disposal procedures. LEDs are free from these harmful substances, making them a more environmentally responsible choice. When you factor in their reduced energy consumption, LEDs represent a significantly greener lighting solution for high-ceiling applications.

As one industry professional put it, “LEDs have gained in popularity since they deliver better light output and quality while using less energy. And due to a long life cycle, they are easier and less costly to maintain. Upgrading your lamps alone or both lamps and fixtures will significantly reduce your warehouse’s electrical expense.”

The bottom line? LED lighting for high ceilings isn’t just better than traditional options – it’s better in virtually every way that matters: energy use, lifespan, maintenance, light quality, and environmental impact.

Benefits of Using LED Lighting in High-Ceiling Spaces

When it comes to illuminating spaces with soaring ceilings, LED lighting for high ceilings delivers an impressive array of benefits that go far beyond simply brightening a room. These advantages touch everything from your bottom line to workplace safety and environmental impact.

Energy Efficiency and Cost Savings

Let’s talk dollars and cents first, because this is where most of our clients see immediate impact. Switching to LED high bay lighting can slash your energy consumption by up to 70% compared to those old-school metal halide or high-pressure sodium fixtures. That’s not a small number!

I remember working with a distribution warehouse here in Houston that was struggling with sky-high electricity bills. After switching from their outdated T12 fluorescent tubes to modern LED high bay lights, their monthly electricity costs plummeted by nearly 60%. But here’s the kicker – the space was actually brighter and more evenly lit than before!

There’s another benefit many folks don’t consider: heat reduction. Traditional lighting puts out a ton of heat, which means your AC has to work overtime. Here in Houston, where summer feels like we’re all living in a sauna, the reduced heat output from LED lighting for high ceilings can make a noticeable dent in cooling costs.

Most of our clients see their LED systems paying for themselves within 2-3 years just through energy savings. Factor in the reduced maintenance needs (which we’ll get to in a moment), and the financial case becomes even more compelling. With a minimum lifespan of 50,000 hours – that’s over 5 years of continuous operation – you’ll be saving for a long time to come.

Improved Illumination and Light Quality

Numbers aside, the quality of light from LED high bays simply outperforms traditional options in ways that make a real difference in day-to-day operations.

First, let’s talk about even light distribution. Have you ever walked through a warehouse with traditional lighting and noticed how some areas are super bright while others feel like you need a flashlight? LED lighting for high ceilings eliminates those annoying “hot spots” and shadows, providing consistent illumination throughout your space. This uniformity isn’t just about aesthetics – it improves safety and helps workers perform tasks more efficiently.

The color rendering index (CRI) is another game-changer. While this might sound technical, it simply measures how accurately a light source shows true colors. LED high bays typically offer CRI ratings approaching 90, compared to the 65-80 range of traditional lighting. This means colors appear more vivid and true to life, which is crucial if you’re doing quality control, manufacturing work, or running a retail space where product appearance matters.

I’ll never forget visiting a retail client with 25-foot ceilings who switched to 4000K LED high bays. Not only did their energy bills drop, but the store manager was thrilled to report that customers were spending more time browsing and sales had increased. The lighting created an environment that was both flattering to merchandise and comfortable for shoppers.

Another huge advantage is the ability to customize your color temperature. LED lighting for high ceilings comes in options ranging from warm white (3000K) to cool white (5700K). This flexibility means you can create the perfect atmosphere for your specific needs:

Warmer temperatures create a cozy, welcoming feel that’s perfect for retail and public spaces, while cooler temperatures improve alertness and visibility in industrial settings where precision matters. At LED Lighting Houston, we help clients find that perfect balance for their unique environment.

And let’s not forget the instant-on capability. Remember how metal halide fixtures need 10-15 minutes to reach full brightness? That’s not just inconvenient – it’s potentially dangerous in emergency situations. LED high bay lights provide immediate, full-output illumination the moment you flip the switch.

With high CRI approaching 90, dramatically reduced environmental impact, and improved safety and productivity throughout your space, LED lighting for high ceilings represents an investment that pays dividends well beyond the energy bill. The combination of superior light quality and significant cost savings explains why we’re seeing businesses across Houston making the switch to LED high bay lighting systems.

Factors to Consider When Choosing LED Lighting for High Ceilings

Selecting the right LED lighting for high ceilings isn’t a one-size-fits-all proposition. There’s an art and science to finding the perfect lighting solution that balances performance, efficiency, and ambiance. Let me walk you through the key considerations that will help you make the best choice for your space.

Assessing Your Space and Lighting Needs

Before you start shopping for fixtures, take some time to really understand your space. I’ve helped hundreds of Houston businesses transform their high-ceiling environments, and the most successful projects always begin with a thorough assessment.

Start with your ceiling height—it’s the foundation of your lighting plan. For ceilings around 8-10 feet, you’ll typically need fixtures in the 80-100 watt range producing 10,000-12,000 lumens. As your ceilings get higher, your power needs increase proportionally. For those impressive 30+ foot ceilings, you’re looking at 300-400 watt fixtures producing upwards of 35,000 lumens to ensure adequate light reaches your floor.

“The biggest mistake I see is underestimating how much light is lost over distance,” says our senior lighting designer at LBX Lighting. “A fixture that looks blindingly bright up close may barely illuminate your workspace when mounted 25 feet up.”

The dimensions of your facility matter just as much as height. A good rule of thumb for a 20-foot ceiling is to space your fixtures about 15-19 feet apart. This spacing changes with ceiling height—closer together for lower ceilings, further apart for higher ones.

Don’t forget to consider what actually happens in your space. A warehouse primarily used for storage has very different lighting needs than one where detailed assembly work takes place. General warehouse storage might only need 10-20 foot-candles, while detailed inspection work could require 50-100 foot-candles or more.

Environmental factors can make or break your lighting system too. Is your space subject to temperature fluctuations? Do you have high humidity levels or airborne dust? For food processing facilities or humid environments, look for fixtures with appropriate IP (Ingress Protection) ratings to ensure longevity.

The Role of Color Temperature in Ambiance

Color temperature might sound technical, but it’s really about how the light feels in your space. Measured in Kelvin (K), it ranges from warm yellowy light to cool bluish light, and it dramatically impacts both the function and feel of your environment.

Warm light (2700K-3500K) creates that cozy, inviting glow that makes people want to linger. I recently helped a Houston-based upscale furniture showroom with 22-foot ceilings install warm-toned LED high bays. The result? Customers stayed longer and the store reported a 15% increase in sales. The warm lighting made their furniture pieces look more inviting and homey.

Neutral light (3500K-4500K) sits in the sweet spot for versatile spaces. It’s my go-to recommendation for offices with high ceilings or educational facilities where you need good color rendering without the stark feel of cooler temperatures. One of our clients, a community college in Houston, found that switching to 4000K LED high bays in their student center created a balanced environment that worked well for both studying and socializing.

Cool light (4500K-6500K) is your productivity powerhouse. It mimics daylight, keeping workers alert and making details pop. For warehouses, manufacturing facilities, and gymnasiums, these higher color temperatures are typically ideal. A local automotive service center with 25-foot ceilings switched from yellowish metal halide fixtures to 5000K LED high bays, and technicians reported they could spot vehicle issues more easily, reducing inspection time by nearly 20%.

“The right color temperature can transform not just how your space looks, but how people feel and perform within it,” I often tell clients. “It’s one of the most powerful yet underappreciated aspects of lighting design.”

Proper Fixture Spacing for Optimal Illumination

Even the best LED lighting for high ceilings can disappoint if poorly spaced. The goal is uniform illumination without hotspots or shadowy corners.

A good starting point is the mounting height rule—spacing fixtures approximately the same distance apart as your ceiling height. But this is just a beginning. Your specific fixtures, their beam angle, and the desired light levels all influence the ideal spacing.

One concept I always emphasize with clients is “cross-over lighting.” Think of it as creating a Venn diagram of light, where each fixture’s illumination pattern overlaps with its neighbors. This overlap ensures there are no dark spots between fixtures. For a warehouse in Houston with 28-foot ceilings, we designed a lighting plan where each fixture’s light pattern overlapped by about 30% with adjacent fixtures, creating beautifully uniform illumination throughout.

Don’t forget to account for obstacles. Those ceiling beams, ductwork, columns, and suspended equipment can create shadows that disrupt your lighting plan. I recommend creating a simple ceiling map that identifies potential obstructions before finalizing fixture placement. Sometimes shifting a fixture just a few feet can eliminate a problematic shadow.

At LBX Lighting, we’ve learned that the most successful high-ceiling lighting projects balance theoretical calculations with practical experience. While lighting design software helps us create detailed illumination models, there’s no substitute for our decades of experience illuminating challenging spaces throughout Houston.

When a local manufacturing facility approached us about their high-ceiling lighting challenges, we didn’t just run the numbers—we visited at different times of day, observed their operations, and spoke with workers about task visibility. This comprehensive approach led to a lighting solution that not only met their technical requirements but also addressed the human factors that mathematical models can’t always capture.

The perfect LED lighting for high ceilings combines science and art—the technical specifications matter, but so does understanding how the space feels and functions for the people who use it every day.

[EXTERNAL LINK]: Industry Today Q. What are the benefits of using UFO LED High Bays?

Installation and Maintenance of LED High Bay Lights

When it comes to LED lighting for high ceilings, proper installation and maintenance aren’t just afterthoughts—they’re critical to getting the most value from your investment. The good news? One of the biggest advantages of choosing LED solutions is how much easier they make your life when it comes to upkeep.

Installation Considerations

Installing lights 20, 30, or even 40 feet up presents some unique challenges, but with proper planning, the process can be straightforward and set you up for years of trouble-free operation.

Most of our Houston clients face a common question: should they retrofit existing fixtures or start fresh? Both approaches have merit. With direct replacement, you can use existing mounting points and wiring, which significantly reduces installation costs and disruption. It’s quick and straightforward—often the right choice if your current fixture layout works well for your space.

On the other hand, a complete redesign gives you the opportunity to optimize your lighting from the ground up. While it costs more initially, it often delivers superior results in terms of coverage and efficiency.

“We often recommend a hybrid approach,” explains our installation team at LBX Lighting. “For a manufacturing facility we worked with last year, we kept about 60% of the existing mounting locations but added strategic new fixtures to eliminate shadows. The client got the best of both worlds—cost savings and dramatically improved lighting.”

The way you mount your fixtures matters too. Hook mounts offer flexibility and quick installation, while pendant mounts provide a cleaner look with more stability. Surface mounting works well for lower high bay applications, and in some spaces, recessed mounting creates that seamless, integrated appearance that many commercial spaces prefer.

Modern LED high bay fixtures also offer exciting control possibilities that weren’t practical with older technologies. Dimming capabilities, motion sensors, daylight harvesting, and networked control systems can all be integrated during installation, dramatically increasing both convenience and energy savings.

“Should you use lighting controls with high bay LED lights? Absolutely,” our lighting design team emphasizes. “Controls like motion sensors can reduce energy usage by up to 30% in warehouses where areas sit unoccupied for periods of time. The technology pays for itself remarkably quickly.”

Maintenance Benefits of LED Lighting

The maintenance advantages of LED lighting for high ceilings are where these systems truly shine—especially in Houston’s commercial and industrial spaces where accessing fixtures can be challenging and disruptive.

Traditional metal halide high bay fixtures typically need lamp replacement every 10,000-15,000 hours. In a warehouse operating 12 hours daily, five days a week, that means climbing up to replace bulbs every 2-3 years. LED high bays, with their 50,000+ hour lifespan, extend that maintenance cycle to 8-10 years under the same conditions.

Think about what that means in practical terms: fewer disruptions to your operations, reduced need for lift equipment rental, lower labor costs, and significantly decreased safety risks associated with working at height. One of our distribution center clients in northwest Houston calculated their maintenance savings after switching to LED high bays—their annual lighting maintenance budget dropped from $12,000 to less than $2,000, an 80% reduction.

Even when maintenance eventually becomes necessary, LED fixtures make the job easier. Many feature modular designs where components can be replaced individually rather than scrapping the entire fixture. Their lightweight construction improves handling safety, and some even offer tool-less access for quick component swaps.

“The first thing our warehouse clients notice after upgrading isn’t actually the energy savings—it’s the fact that their maintenance team isn’t constantly replacing burnt-out lights anymore,” notes our service department. “That alone makes LEDs worth the investment for many businesses with high ceilings.”

Safety and Productivity Improvements

Beyond the obvious maintenance and energy benefits, LED lighting for high ceilings delivers significant improvements in workplace safety and productivity that directly impact your bottom line.

The superior visibility provided by LED high bay lighting transforms high-ceiling environments. With color rendering indexes (CRI) approaching 90, colors appear true and vivid, making it easier to identify products, read labels, and spot potential hazards. The uniform light distribution eliminates the shadowy areas common with older lighting technologies where accidents often occur.

These visibility improvements translate directly to improved safety. Studies consistently show that proper illumination can reduce workplace accidents by 25-50% in industrial settings. When forklifts, heavy machinery, and workers all share the same space, clear visibility becomes a critical safety factor.

“We installed LED high bays throughout our warehouse last year, and our safety incident rate dropped by almost 30%,” reported the operations manager at one of our Houston manufacturing clients. “Our workers report less eye strain and fatigue, especially during night shifts.”

The productivity gains can be equally impressive. Workers make fewer errors when they can clearly see what they’re doing. Order picking accuracy improves, assembly speeds increase, and quality control becomes more effective. These improvements often surprise our clients, who typically focus on energy savings when making the switch.

A food processing facility in east Houston tracked their production metrics before and after upgrading to LED high bay lighting. They finded a 12% increase in production line efficiency—a benefit they hadn’t anticipated when making the switch primarily for energy reasons. Their employees reported feeling more alert and experiencing less eye fatigue during long shifts.

The instant-on capability of LEDs also eliminates the warm-up period required by metal halide fixtures. This means lights can be turned off when areas are unoccupied without worrying about the 10-15 minute restart delay, further enhancing both safety and energy efficiency.

At LBX Lighting, we’ve seen how LED lighting for high ceilings transforms workplaces throughout Houston. The combination of reduced maintenance, improved safety, and improved productivity creates a compelling case for upgrading, even before considering the substantial energy savings.

Case Studies: Applications of LED Lighting in High Ceilings

Nothing demonstrates the value of LED lighting for high ceilings quite like real-world examples. At LBX Lighting, we’ve had the privilege of helping numerous Houston businesses transform their spaces with custom high bay LED solutions. These stories showcase not just energy savings, but genuine business improvements that go far beyond the electric bill.

Commercial Applications

Retail Environment Change

I remember walking into a large Houston retail store with 22-foot ceilings and immediately noticing the problems. Their outdated metal halide system created a patchwork of bright spots and shadows. The store manager was frustrated with constantly replacing burnt-out lamps and the disruption it caused shoppers.

“We were spending more time on ladders than helping customers,” he told me during our initial consultation.

We designed a solution using linear high bay LED fixtures with a pleasant 4000K color temperature. The change was remarkable. Products that once looked dull suddenly popped with vibrant, true-to-life colors. The even illumination eliminated shadows between aisles, and the entire store felt more inviting.

The numbers told an impressive story too: energy consumption dropped by 64%, and their annual lighting maintenance costs plummeted from $8,500 to less than $1,000. But what really surprised them was the 15% sales increase in departments that had previously been poorly lit.

“The new LED lighting has transformed our space,” the store manager shared months later. “Products look better, customers stay longer, and our team spends zero time dealing with burnt-out lights. It’s been a win across the board.”

Gymnasium Illumination

A Houston community sports center with soaring 28-foot ceilings presented a different challenge. Their fluorescent high bay system was creating glare issues during basketball games, and players complained about “dead spots” on the court where lighting was inconsistent.

We knew this environment needed specialized attention, so we installed UFO high bay LED fixtures with carefully selected optics to minimize glare – crucial for sports like basketball and volleyball where players are constantly looking upward. We chose 5000K fixtures for their daylight-like quality, which helps athletes track fast-moving objects.

The center’s director was amazed by the results. “It’s like playing in natural daylight now,” she said. Light levels more than doubled, from a dim 30 foot-candles to a bright, uniform 75 foot-candles across the entire court. Energy use dropped by 58%, but more importantly, players and coaches raved about the improved visibility.

An unexpected bonus? The improved lighting met broadcast standards for recording games, allowing the center to livestream tournaments for parents who couldn’t attend in person.

Industrial Applications

Warehouse Efficiency Upgrade

One of our most dramatic changes involved an 80,000-square-foot Houston distribution warehouse with towering 32-foot ceilings. Their aging 400W metal halide fixtures were creating serious operational problems – order pickers were struggling to read labels, and the dark areas between aisles had become safety hazards.

We designed a comprehensive LED lighting for high ceilings solution using 240W UFO high bay fixtures with crisp 5000K color temperature. But we didn’t just replace fixtures – we optimized their placement based on the warehouse’s specific racking layout and installed occupancy sensors in low-traffic areas. Near the loading docks with skylights, we added daylight harvesting controls to maximize natural light usage.

The warehouse manager was initially skeptical about the investment, but the results quickly won him over. Energy consumption dropped by a staggering 71%, generating annual savings exceeding $42,000 in energy costs alone. More impressive were the operational improvements: order picking accuracy improved by 9%, and workplace accidents decreased by 23% in the first year.

“I never realized how much our poor lighting was costing us beyond the electric bill,” the warehouse manager told me. “The ROI was just 19 months, but the safety improvements alone would have justified the project.”

Manufacturing Facility Modernization

A precision manufacturing facility in Houston with 26-foot ceilings presented unique challenges. They needed lighting that would support detailed visual inspection while reducing their substantial energy costs. Their existing T5 fluorescent system was not only energy-intensive but created inconsistent lighting conditions that affected quality control.

For this client, color accuracy was critical. We installed linear high bay LED fixtures with exceptionally high CRI (90+) at 5000K color temperature, ensuring inspectors could detect even subtle color variations. We also created task-specific lighting zones in inspection areas and implemented programmable controls to adjust light levels based on production schedules.

The facility’s change went far beyond energy savings. While they did reduce consumption by 63%, the production improvements were even more valuable. Quality control rejection rates decreased by 7.5% – a significant financial benefit given the high value of their products. Workers reported less eye strain and fatigue during long shifts.

“It was great!” the plant manager enthusiastically shared. “They were very helpful. Everything that came up was handled smoothly, the money came in place when it was needed, and it was a very smooth transition. The improved lighting has made a noticeable difference in our quality metrics.”

These real-world examples demonstrate why LED lighting for high ceilings delivers benefits that extend far beyond the electric bill. From retail spaces where products look more appealing to warehouses where workers stay safer, proper high bay lighting transforms how spaces function at a fundamental level.

Want to explore high ceiling lighting options for your space? Visit our High Ceiling Lighting Solutions page for more information or check out what Industry Today has to say about the benefits of UFO LED High Bays.

Frequently Asked Questions about LED Lighting for High Ceilings

How Many LED High Bay Lights Do I Need?

Figuring out the right number of LED lighting for high ceilings fixtures doesn’t have to be complicated, but it does require attention to several important factors.

Most people start with a simple square footage calculation – multiply the length by width of your space to get total square footage, then divide by the coverage area of your chosen fixture. But that’s just the beginning of the story.

Your ceiling height plays a crucial role in determining fixture quantity and spacing. As your ceilings get higher, you’ll either need more fixtures or higher-wattage options that produce more lumens. For instance, if you have 10-foot ceilings, you’ll typically want to space fixtures about 12-15 feet apart. With 20-foot ceilings, that spacing increases to about 15-19 feet, and for those really towering 30+ foot ceilings, you’re looking at spacing around 19-35 feet apart.

“One of the biggest mistakes I see is when clients try to use a one-size-fits-all approach to high ceiling lighting,” says our lighting design team at LBX Lighting. “Each space has its own unique requirements based on not just dimensions, but also the activities taking place there.”

Speaking of activities, the desired light level (measured in foot-candles) significantly impacts how many fixtures you’ll need. Basic warehousing might only require 10-20 foot-candles, while retail spaces typically need 30-50. Manufacturing environments often need 50-75 foot-candles, and precision work areas might demand 75-100+ foot-candles. The higher your desired light level, the more fixtures (or higher-output fixtures) you’ll need.

Don’t forget to account for obstructions in your space. Racking systems, machinery, building columns, and other elements can block light and create shadows. These obstructions might necessitate additional fixtures or strategic placement to ensure uniform illumination.

For spaces larger than 5,000 square feet or with complex layouts, we strongly recommend getting a professional lighting plan. Our lighting specialists at LBX Lighting can create detailed photometric analyses that show exactly how light will distribute throughout your space, ensuring you get optimal coverage without wasteful over-lighting.

Can LED High Bay Lights Be Dimmable?

Yes! Many LED lighting for high ceilings fixtures offer dimming capabilities, though it’s important to note that not all models include this feature. Dimmability adds tremendous versatility to your lighting system while potentially boosting your energy savings even further.

Dimmable high bay lights offer several compelling benefits. First, they allow you to optimize energy usage by adjusting light levels based on specific needs rather than always operating at full power. They also provide adaptability, letting you modify lighting for different tasks or times of day. In spaces with skylights or large windows, dimmable fixtures can integrate beautifully with natural daylight, automatically adjusting output as sunlight levels change. As an added bonus, operating LEDs at less than full power can actually extend their already impressive lifespan.

“We installed dimmable LED high bays in a Houston distribution center last year,” shares one of our project managers. “They programmed different light levels for various operational modes – 100% during picking operations, 70% during restocking, and 30% during cleaning and maintenance. The energy savings were substantial, and workers appreciated having appropriate light levels for each activity.”

Several dimming technologies are available for high bay fixtures. The most common is 0-10V dimming, which uses a control voltage between 0 and 10 volts to adjust light output. For more sophisticated needs, DALI (Digital Addressable Lighting Interface) offers individual fixture addressability. Wireless dimming provides flexibility without requiring additional control wiring, while occupancy-based dimming automatically adjusts light levels based on detected activity.

When implementing dimmable LED high bay lighting, make sure to verify compatibility between your fixtures and dimming systems. Plan for appropriate control wiring during installation, train your team on proper system operation, and develop lighting schedules that balance energy savings with operational needs.

What is the Lifespan of LED High Bay Lights?

The remarkable longevity of LED lighting for high ceilings is one of its most compelling advantages, especially when you consider how challenging and disruptive it can be to replace fixtures in high-ceiling environments.

Quality LED high bay fixtures typically have a rated lifespan of at least 50,000 hours, with many premium products extending to 100,000 hours or beyond. To put that in perspective, 50,000 hours equals nearly 6 years of non-stop, 24/7 operation. In a more typical business setting operating 12 hours daily, five days a week, that translates to over 16 years of service! Compare that to traditional metal halide lamps that typically last only 10,000-15,000 hours, and you can see why the switch to LED makes so much sense for high-ceiling applications.

It’s worth understanding that the lifespan rating of LEDs typically refers to L70 – the point at which the fixture still produces 70% of its initial light output. Unlike traditional lamps that simply burn out, LEDs gradually produce less light over time, which means you’ll rarely experience sudden failures that leave areas completely dark.

“One of our clients in the manufacturing sector was replacing metal halide bulbs every 8-10 months,” recalls our service manager. “Since upgrading to LED high bays five years ago, they haven’t had to replace a single fixture. The reduction in maintenance disruptions alone has made their investment worthwhile, not to mention the energy savings.”

Several factors can affect how long your LED high bay fixtures will actually last. Operating temperature is critical – LEDs are sensitive to heat, so fixtures with better thermal management typically last longer. Driver quality matters too; often, the driver (the electronic component that regulates power to the LEDs) fails before the LEDs themselves. Usage patterns, environmental conditions like humidity or dust, and voltage stability can all impact longevity as well.

To maximize the lifespan of your LED high bay lighting, start by selecting quality fixtures from reputable manufacturers with proven track records. Ensure proper installation following manufacturer guidelines for mounting and electrical connections. Maintain an appropriate operating environment with adequate ventilation and avoid extreme temperatures. Consider installing surge protectors to shield fixtures from electrical spikes. Finally, implement controls thoughtfully, using dimming and scheduling to reduce operating hours and intensity when full output isn’t needed.

At LBX Lighting, we’ve consistently found that quality LED high bay fixtures properly installed in appropriate environments regularly exceed their rated lifespans. One of our early Houston clients installed LED high bay fixtures back in 2013 that are still operating at over 85% of their original output after nearly a decade of daily use – a testament to the long-term reliability of modern LED technology when properly specified and installed.

Conclusion

Choosing the right LED lighting for high ceilings isn’t just about illumination—it’s an investment that touches every aspect of your operation. Throughout this guide, we’ve walked through the many considerations that should shape your lighting decisions, from technical specifications to real-world applications.

Key Takeaways

When I sit down with clients to discuss their high-ceiling lighting needs, I always emphasize how transformative proper LED lighting can be. The benefits extend far beyond simply “better lights”—they reshape how spaces function and feel.

LED high bay lighting dramatically cuts energy consumption by up to 70% compared to traditional options. One of our Houston warehouse clients recently called me just to share their excitement about their first post-installation electric bill. “Michael,” they said, “I had to double-check the statement—I thought they’d made a mistake!”

The initial investment in quality LED fixtures pays for itself remarkably quickly. Between energy savings, virtually eliminated maintenance costs, and improved operational efficiency, most of our clients see complete ROI within 2-3 years. After that, it’s all savings flowing to your bottom line.

Selecting the right fixtures and placing them strategically makes all the difference. I’ve walked into too many spaces where someone installed LED fixtures without proper planning—resulting in uneven lighting, glare, or inadequate illumination. Taking the time to consider your ceiling height, space dimensions, and specific activities transforms good lighting into exceptional lighting.

Color temperature might seem like a small detail, but it profoundly impacts how people experience your space. For a retail client with high ceilings, we installed 3500K fixtures that created a warm, inviting atmosphere that complemented their merchandise. For a manufacturing facility, we used 5000K lighting that improved visual clarity and helped maintain worker alertness during long shifts.

Smart controls amplify the benefits of LED lighting. I love showing clients how integrating occupancy sensors, daylight harvesting, and programmable schedules can reduce energy consumption by an additional 20-30% beyond the baseline LED savings. One distribution center we worked with was able to reduce their lighting energy usage by nearly 85% through the combination of LED fixtures and intelligent controls.

At LBX Lighting, we understand that navigating the technical world of LED lighting for high ceilings can feel overwhelming. Every space has unique requirements, and sorting through specifications, options, and technical details isn’t something most facility managers want to tackle alone.

That’s why we offer comprehensive lighting assessments, custom design services, and expert installation for businesses throughout Houston and surrounding areas. Our approach is consultative rather than transactional—we want to understand your space, your operations, and your goals before recommending solutions.

With over 30 years of experience illuminating Houston’s commercial and industrial spaces, we bring both expertise and local understanding to every project. From initial concept through final installation and beyond, our team ensures your high-ceiling lighting project delivers maximum value and performance.

Whether you’re retrofitting an existing facility or planning lighting for new construction, investing in proper LED lighting for high ceilings pays dividends in multiple ways. Beyond the obvious energy savings, you’ll create a safer, more productive environment that supports your business goals and improves your space.

Ready to transform your high-ceiling space with lighting that combines efficiency, performance, and value? Contact our Houston lighting experts today and find how LBX Lighting can illuminate your path to operational excellence. We’re here to light the way—no ladder required.